Regardless of the nature and scale of your project, materials are crucial for success. Having the right ones means you’ll get the product that fulfills your boldest expectations. On the other hand, choosing it wrong can cost you dearly in every sense of the word. That’s why it’s important to be well-versed in the materials you are supposed to use, but it is even more important to know how to choose your perfect fit in the sea of available options. To help you with the process of selection here is how to make the right choice and get the materials that live up to the challenge and do not cost you a fortune.

Look For Cost-Effective Solutions

Regardless of the size, type, and purpose of your project, it is impossible to make even the most brilliant idea a reality without a certain amount of money. Of course, everything has its own price and you cannot just choose a different material because it comes with a nicer price tag. However, what you should strive for is always figuring out the most cost-effective solution able to deliver the highest quality of your product.

We live in the era of modern technologies that offer plenty of opportunities to save money, at the same time, enjoying the full benefits of the latest discoveries. For instance, more and more manufacturers switch to state-of-the-art plastic materials because as can be clearly seen at www.shapesplastics.com they provide infinite possibilities for application across a wide variety of industries. Suitable even for the most challenging projects, plastic materials are often the best choice not only in terms of cost-effectiveness but also in durability and usability.

Availability Is Key

In search of that sought-after material intended to become a real game-changer for your future project, a great many manufacturers often got too far, literally. Unless you do not have incredibly specific requirements, always take a look at your local market first. Bringing stuff from another state or even country is not only time-consuming but also expensive. Chances are, you will have to postpone your work because shipping usually doesn’t go that smoothly. There is no dilemma: prioritize materials that are widely available in your area, so you won’t have to stop the manufacturing process because you run out of supplies.

Ask For Expert Advice

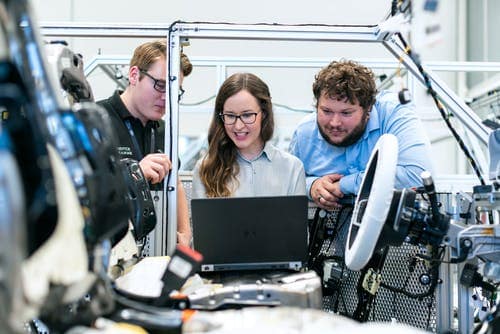

If your new project involves materials you haven’t worked with before or it’s about a novelty product, do not be afraid to seek expert help. If you are not quite sure how a certain material will behave when exposed to too high or too low temperatures, water, strong pressure, or whatever is in question, do not leave the success of your project to chance, consult a specialist who is well-versed in the subject. It may cost you extra but this sum is not even close to eventual losses caused by the wrong choice of material.

Get The Best Quality You Can Afford

Determining the type of material that caters directly to your needs is just the first step towards getting a top-notch product. The same material can be offered by different providers and often, the quality is not the same. Your primary goal is to get the best you can buy for your money, therefore do not just pick the company that is the cheapest on paper. Do a bit of research and your due diligence to strike that sweet spot – a balance between the quality and the price. By the way, the most expensive option is not always the most quality one, sometimes you just pay for the brand that has invested a lot of bucks in paid advertising.

Think Of Sustainability

Every responsible manufacturer strives to produce a quality product that can serve the purpose for many years to come – not only because they want to please their customers but also because they do love our beautiful planet. When choosing materials for your project, think of their sustainability and the possible effect on the environment and lives of future generations. Again, locally found materials are usually the best bet given that they eliminate lengthy transportation and don’t contribute to carbon emissions. It is a great feeling to know that your project hasn’t done any harm to mother nature, isn’t it?

Obviously, the materials you choose for your project play a crucial role in the quality of your end product so be sure to set aside enough time and do your homework. Do not rush to conclusions, look for the most cost-effective solutions that will deliver the best results.

You may also like

-

Common Misconceptions About Disability Law and Lawyers

-

Finding the Right Disability Lawyer: Key Factors to Consider

-

Creating Families Across Canada: The Journey Through Adoption

-

Understanding the Practical Applications of Ibutamoren in Research

-

Navigating Regulations and Permits in the Crude Oil Hauling Industry